Rules for working at heights in virtual reality - KGHM is implementing another innovative work safety solution

Training on the rules for working at heights in virtual reality - the KGHM has completed the 2nd stage of an innovative solution related health and safety rules at the Głogów Copper Smelter. The employees undergo training by learning the safety rules and procedures using VR goggles.

At the Głogów Copper Smelter, the employees are already using the technology during training in copper melting and drain opening plugging. The latest training consists of three scenarios. The trainees take on the role of a worker who performs cleaning work at height on the substructure of an overhead crane, can fall from a height due to a failure to follow the rules, and test how to provide help to a colleague who is hanging in a harness.

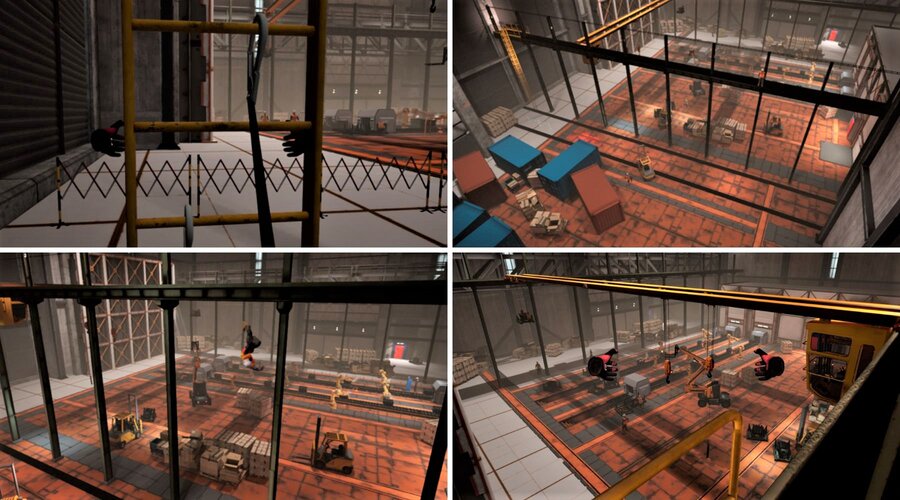

With the help of special goggles and pads, workers at the smelter train correct behavior and procedures for the performance of work at height. Special software renders the interior of the plant in small detail. All components of the infrastructure are included.

The trainee holds the controllers in his hands and can (literally) go through the entire process of getting ready for work and all the subsequent activities. The training is very visually appealing and its form resembles a computer game.

The use of VR technology effectively engages the user’s muscle memory. The movements that are practiced in virtual reality correspond exactly to the actions that are performed at work. As a result, the employee undergoes hands-on training without even entering the facility. Thus, his efficiency and motor coordination are much higher than those he would have if he worked only based on the theoretical knowledge he has previously acquired.

The project at the KGHM’s Głogów Copper Smelter was carried out by the KGHM’s Centrum Analityki company, in cooperation with the VR-Learning company.