Deepest in Poland - KGHM has a mining pit 1,348 meters deep

At 1,348 meters is the deepest mining pit in Poland - KGHM Polska Miedź's GG-1 shaft in Kwielice is one of the most important investments in the copper giant's history and the largest underground project in the non-ferrous metals industry in Europe. In June, the key connection between the shaft and the Rudna Mine was made.

The technical connection, i.e. the merge of excavations from the Rudna Mining Plants to the GG-1 shaft, was successfully carried out on June 14 this year. Work is now underway there, which will allow new amounts of fresh air to be supplied to the mine workings. This will definitely improve working conditions underground.

The shaft is ready for its development and equipping with the necessary installations for the target period. A three-meter layer of concrete has been poured on the bottom. The two basic parameters of the GG-1 shaft are its depth - 1,348 meters, and its diameter with the casing, which is 7.5 meters. This is an intake-air shaft that will be used to transport people and materials.

"KGHM is a jewel in the crown, and the GG-1 shaft is an amazing project that will affect the safety of the miners. I am full of admiration for all those who undertook this project. Everything is done so that miners can work in the best possible conditions. The GG-1 shaft is also a business, industrial, economic project. These are copper deposits that can be mined for decades to come," said Elżbieta Witek, Speaker of the Polish Parliament.

"The GG-1 shaft is a strategic investment by KGHM. It will provide the air that will enable us to exploit the Deep Głogów deposit at depths that were previously inaccessible to us. We are a global company, but domestic production is of fundamental importance to the company. The completed shaft, first of all, ensures safety, but also promotes more efficient work by the miners," said Tomasz Zdzikot, President of the Management Board of KGHM Polska Miedź S.A., during a press conference.

The GG-1 shaft is of fundamental importance for the development of KGHM Polska Miedź S.A.. It will make it possible to open up new areas of the copper deposit and prolong the operation of the Polkowice-Sieroszowice and Rudna mines. The investment will also improve ventilation and air-conditioning conditions for the miners and will shorten the routes of crews' access to the pits.

Shaft in numbers

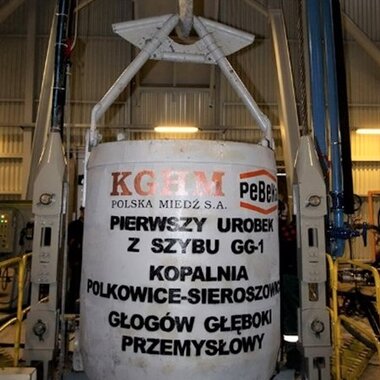

The GG-1 shaft complex is being built as part of the Deposit Access Program conducted by the Department of Mining Structure Development at KGHM's Head Office. The work was carried out by a KGHM Group company, PeBeKa. The GG-1 shaft is one of the most important facilities that will serve to open up the Deep Głogów Mining Area

The estimated industrial copper ore resources are nearly 265 million tons, with an average copper content of 2.40 %. This represents about 25 % of copper resources and more than 30 % of silver resources in all of KGHM's concessioned areas in Poland. Access to these resources will secure the continuity of copper ore mining for many years to come.

According to investment plans, in the years 2028-35, i.e. during the period of the greatest intensity of mining work, production from the Deep Głogów area is expected to be 10-11 million tonnes of ore, from which it will be possible to obtain about 200-220 thousand tonnes of electrolytic copper per year.

History of the investment

Construction of the GG-1 shaft began in 2010. Two years later, the shaft headframe, which is one of the tallest ever erected by KGHM, began to be built. It is 45.5 meters high and weighs 1,100 tonnes. The equipment used in pilling the shaft includes a complex hoisting system with more than a dozen steel cables. Each is more than 1,500 meters long, some weighing as much as 20 tonnes.

In 2013, one of the key stages of construction began: the freezing of the rock mass preceding the shaft drilling. Brine was then pumped into 40 freezing holes. The first bucket of excavated material left GG-1 on December 11. A year later, specialists reached layers of solid rock at a depth of 393 meters. It was then that the method of shaft drilling was changed from mechanical excavation of the rock mass to the blasting method.

To build up the first section of GG-1, PeBeKa employees used 466 iron rings, which protected the shaft from flooding with water from Tertiary and Triassic layers. To comprehensively protect GG-1 from the effects of water inflow, a modern so-called cascade drainage system was installed in the shaft. In subsequent years, as work progressed on further drilling the shaft, further elements of the drainage system were added. A total of eight stations were built there, pumping water in a cascade system from the bottom of the shaft to the surface.

This year, March also marks the 60th anniversary of the mining of the first bucket of copper ore in the Copper Belt. It happened on March 20, 1963, in the L-III shaft belonging to the Lubin mine. One of the pioneers of Polish Copper, the late Jan Ulrich recalled, that "among the ore, we noticed a large chunk of dolomite, in which large veins of copper sulfides were visible. The joy was enormous. I thought: at last we have reached the deposit."

The GG-1 shaft is the company's thirty-first shaft in the Copper Belt. Meanwhile, preparatory work has begun on the construction of another important facility in the Deposit Access Program in the Deep Głogów and Gaworzyce mining areas. The GG-2 shaft, located in the municipality of Żukowice, will have a personnel transport-material function.