The highest quality for clean air – KGHM commissioned a new plant

The copper industry leader has just commissioned a Post-Process Gas Treatment Plant at the Legnica Copper Smelter. This innovative facility virtually completely cleans the gases of mercury and arsenic, leaving only mainly nitrogen oxides, carbon dioxide, and a little sulfur dioxide. This is the first such facility in Poland and one of only a few in the world.

The plant is another element of the BATAs Program successfully implemented by KGHM. The cost of the project is nearly PLN 120 million.

Purification at the highest level

The SOLINOX plant at the Legnica Copper Smelter treats waste gases of sulfur dioxide, and an additional recently commissioned unit will clean the gases of arsenic and mercury to a level of no more than 0.05 mg/Nm3.

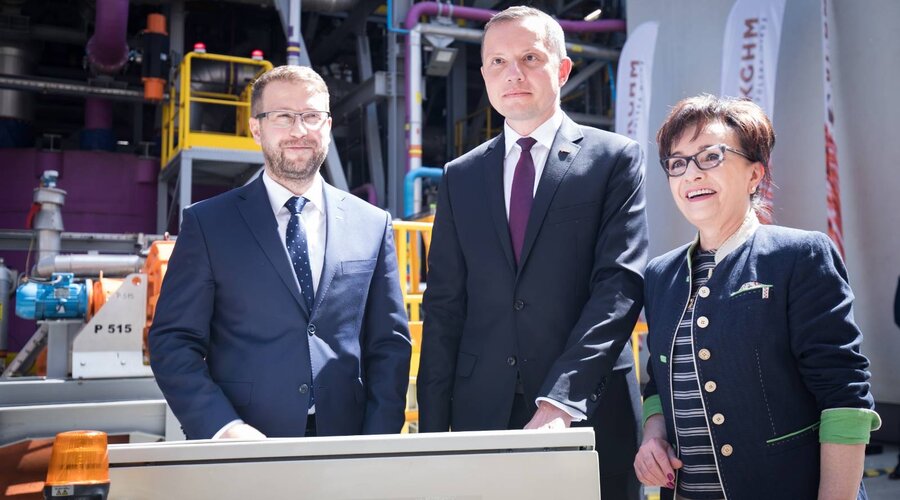

“KGHM is one of our national champions, a leader and promoter of transformation. The company not only supplies the materials essential for economic growth and the development of new technologies that help stop climate change, but itself uses the highest quality solutions to protect the environment. In doing so, it takes care of its surroundings and local communities. The plant being commissioned today is proof of the highest quality and responsibility for the surroundings,” said Elżbieta Witek, the Speaker of the Sejm, during the commissioning ceremony.

“The plant at the Legnica Copper Smelter is another strategic investment by KGHM in environmental protection, and a pro-environmental project worth more than PLN 100 million. The specially designed unit will allow us to achieve effects that have not been unattainable before. We are the only company in Poland to implement this high-tech method. Environmentally friendly solutions at the highest level - this is how we operate at KGHM, which is the leader of green transformation in Poland,” summarized Tomasz Zdzikot, the CEO of KGHM Polska Miedź S.A.

High-end technology

The new plant purifies gases based on the calomel technology. This is an internationally proven method whose advantages include low amounts of waste produced.

The plant consists of two wet electrostatic precipitators in the first treatment stage, two in the second stage, and a calomel tower located between them. The gases exiting the existing cooling tower are routed to the first-stage wet electrostatic precipitator unit, after which they go to the absorption tower of the calomel system where they are purified to remove mercury compounds. The final dedusting and cleaning of the gas are carried out in the second-stage wet electrostatic precipitator unit.

This key project was completed in the very short period of just over ten months. Bipromet, a KGHM Group company, was responsible for the design and construction of the system.

Strategic environmental protection

Environmental protection is one of the strategic areas for KGHM. In 2022, the company spent about PLN 250 million on pro-environmental investment projects. KGHM has adopted ambitious climate and environmental policies that include its environmental goals and commitments, including the goal of achieving climate neutrality by 2050. Since 2017, the company has been implementing the “Program for adaptation of KGHM’s process systems to the requirements of the BAT (best available techniques) Conclusions for the non-ferrous metals industry, together with a reduction of arsenic emissions.” Implementation of the BATAs program has already led to a 79% decrease (in 2021) in particulate emissions from electrolytic copper production compared to 2010.

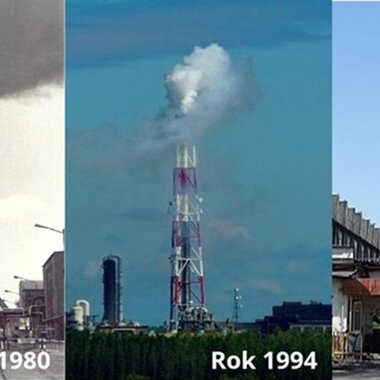

Jubilee of the Legnica Copper Smelter

2023 is a special year for the Legnica Copper Smelter, a division of KGHM, as it is celebrating its 70th anniversary and opening a new chapter in its history. Work is underway there to implement the Legnica Hybrid Smelter program. The idea behind the project is to utilize the potential of scrap copper by implementing the assumptions of the Closed-Circuit Economy. This will allow the smelter to process recycled materials, with the ability to melt its own concentrates or concentrates from external sources. The division is already a leader in KGHM in the area of cathode copper production based on non-primary source feedstock (ore). The electrolytic copper produced at the Legnica Hybrid Smelter contains 70 percent of various types of scrap.

KGHM for cleaner air

KGHM considers environmental protection as one of its strategic areas. In 2022, the company spent about PLN 250 million on pro-environmental investment projects. Its modernization of production and technological solutions always takes into account environmental aspects.