KGHM has calculated the environmental footprint of its standard-bearing products

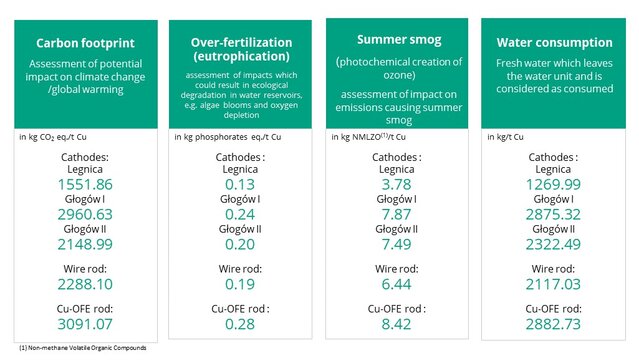

KGHM ordered an analysis to be made of the environmental and carbon footprints of its products: cathodes, wire rod and Cu-OFE rod – the Mineral and Energy Economy Research Institute of the Polish Academy of Sciences (PAN) performed an analysis in compliance with ISO standards, and prepared environmental declarations. The copper products of KGHM have a footprint which is lower than the global average of such indicators.

“In KGHM we have a strategy and policies covering activities to protect the environment, plans to reduce emissions, and we treat these subjects with a sense of great responsibility. We are familiar with the phrase climate competitiveness, which is becoming a key in the global economic market. The carbon footprints of KGHM’s products shows one thing – we know perfectly well what we are doing, we are striving to protect our external environment, we are investing and achieving our goals,” said Tomasz Zdzikot, President of the Management Board of KGHM Polska Miedź S.A.

Tomasz Zdzikot added that responsible environmental management by corporations begins with the measurement of how a given company impacts the environment and climate. For this reason the decision was made to calculate the environmental footprint, including the carbon footprint of its copper products. The analysis comprised a wide assortment of parameters, including greenhouse gas emissions, starting from the mining of the raw material to the use of energy in the production process and finally the preparation of the end product.

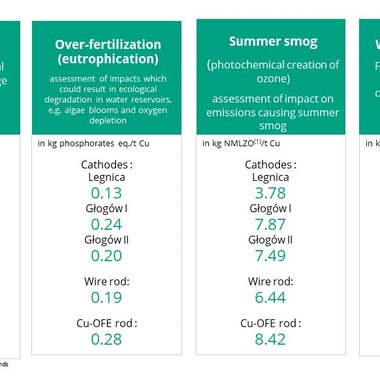

Environmental footprint of KGHM products:

A Green KGHM

The analyses conducted confirm that the metallurgical plants of KGHM (the Legnica Copper Smelter and Refinery, the Głogów Copper Smelter and Refinery and the Cedynia Wire Rod Plant) produce metal responsibly and in compliance with the highest standards. The metallurgical plants have implemented an Environmental Management System compliant with ISO 14001. Moreover, the divisions in Legnica and Głogów hold the internationally-recognised Copper Mark certificate. KGHM expects that its Cedynia Wire Rod Plant will also soon join this group.

In response to the global challenge associated with sustainable development, KGHM adopted an ambitious Climate Policy, in which it declared the intention of achieving climate neutrality by the year 2050. Over the next seven years the Company will strive to reach the goal of having 50 percent of its power needs come from its own sources, including RES. Currently, the operation of the CCGT natural gas-steam blocks of KGHM Polska Miedź S.A. can cover up to 20 percent of its needs for electrical power.

KGHM, by diversifying its power sources throughout the Group, also intends to rely on energy from the sun, wind and hydrogen. The Company is building solar power plants and is continuing projects involving offshore wind power and hydrogen sources. In addition, KGHM is engaged in developing nuclear power in Poland.

Products at a global level

The copper cathodes produced in the Głogów and Legnica smelter/refineries are the basic product of KGHM Polska Miedź S.A. They are characterised by their very high quality, as attested to by certificates issued by the London Metal Exchange, the Shanghai Futures Exchange and the International Energy Exchange in Shanghai (INE). Quality is guaranteed by the brands: HML for Legnica, HMG-S for Głogów I and HMG-B for Głogów II, under which they are registered on the London Metal Exchange as grade „A”.

8 mm copper wire rod is produced by the Contirod® continuous smelting, casting and rolling process, mainly using cathodes produced by the Company’s metallurgical divisions, in the Cedynia Wire Rod Plant Division of KGHM Polska Miedź S.A. Cedynia produces wire rod in five quality classes, matched to the needs of individual customers. The product is primarily used in the cable, electromechanical and electrotechnical industries. The wire rod market, due to its nature, is highly competitive and demanding.

In 2022, production of wire rod and OFE rod by KGHM Polska Miedź S.A. amounted to 284.8 thousand tonnes, or nearly 11% of European production. This result makes KGHM one of Europe’s leading producers of these copper half-finished products.