A spectacular investment in clean air in Lower Silesia. KGHM is constructing the Gas Treatment Plant at the Legnica Copper Smelter and Refinery

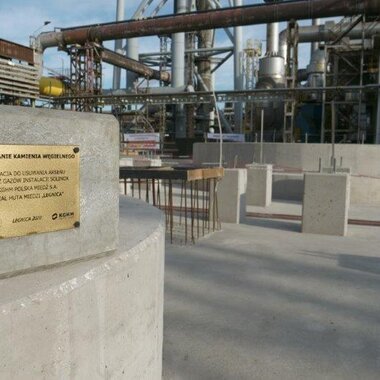

Despite this unusual year, marked by epidemic procedures, KGHM is starting another important investment for the environment at the Legnica Copper Smelter and Refinery, in accordance with the plan. Foundations have already been laid at the construction site of the innovative Post-Process Gas Treatment Plant. The installation, which will reduce pollution by up to 99%, will be ready for operation next year.

- The pandemic has not altered our strategy. We have launched another significant investment, worth approximately PLN 110 million. KGHM has opted for clean air, energy efficiency and green energy. This way, we are changing the image of the Polish industry year by year. In each of these areas, we already have significant achievements and plans for the future - says Marcin Chludziński, President of the Management Board of KGHM Polska Miedź S.A.

Innovative installation

The new installation at the Legnica Smelter and Refinery will take over the pre-treated process gases and direct them to the existing SO2 absorption tower. From there, fumes of negligible pollution content will be emitted into the atmosphere. The gas will contain only oxygen, nitrogen, water, carbon dioxide and a small amount of sulphur dioxide. Ultimately, the investment will reduce the residual pollution by up to 99%.

Investment in line with European standards

Radosław Stach, KGHM Vice President for Production, emphasises that the installation will make it possible to process various types of concentrates in the smelter according to the highest environmental standards. – It is one of the components of the BATAS programme intended to adapt our installations to environmental requirements. It is a groundbreaking investment, not only in the Legnica Smelter and Refinery, but in KGHM as a whole - adds the Vice President.

The installation will consist of two wet precipitators in the first cleaning stage, further two in the second stage and a calomel tower. Michał Topolnicki, Executive Director of the Legnica Smelter and Refinery adds that the investment is being developed in cooperation with KGHM, BIPROMET. - The installation will constitute an additional node in the existing Solinox desulphurisation process line at the Smelter. The key task is to clean up the gases - says the Executive Director.

Construction in figures:

- Foundation dimensions - 31.8 x 31.8 m

- Concrete used to build the foundations - 1 280 m3

- Installation height – 31 m